The installation of the wireless card in the roboard is as in the following 5 steps.

(1) Getting the needed tools

Beside the packages to the linux, we might use usefull tools like putty, a ssh terminal to access the roboard if you know the IP and WinSCP to access the roboard folders as an easy way to manage and drag and drop files or folders, from windows environment.

Getting the linux tools

Get the bzip2 # apt-get install bzip2

Get the make # apt-get install bzip2

Get the gcc # apt-get install gcc

Get the unrar #apt-get install unrar-free

Get the wireless-tools # apt-get istall wireless-tools

Get the wpa supplicant # apt-get install wpasupplicant

(2) Installing the compatible version of linux

To install the wireless card VT6655 on the roboard we need first do install a linux 2.6.30 version, we can do this by copying the Linux-Image-2.6.30-vortex86mx deb file to the roboard and then install.

After burning the pendrive instead copying the image 2.6.34.1 version to the root directory of the pendrive, copy the 2.6.30, and follow the rest of the roboard installation.

If your roboard is already installed, just copy the image.deb file to a roboard folder and then, inside the same folder, do

# cd /usr/src

# dpkg -i image.deb

# update-initramfs -k 2.6.30-vortex86mx -c

# update-grub

Reboot the system now and then restart with the 2.6.30 version linux

Use “apt-get remove” to uninstall other version of kernel that might interfere on boot

(3) Copying the needed material to install the card

Download the following link files to you computer and place them on a roboard folder, in our case /usr/src/

config

VT6655-Drivers or Download from VIA site

linux-2.6.30-kernel

(4) Compiling and Installing the 2.6.30 kernel

Decompress the linux 2.6.30 kernel.

# tar -xf linux-2.6.30-vortex86mx.tar.bz2

This might take a long time.

# cd /usr/src/linux-2.6.30

# cp ../config-2.6.30-vortex86mx-apm .config

# make modules_prepare

# rmdir –ignore-fail-on-non-empty /lib/modules/2.6.30-vortex86mx-apm/build

Check if the directory still in there, with the winspc, if it still exists delete it

Now create a link to the folder

# ln -sf /usr/src/linux-2.6.30 /lib/modules/2.6.30-vortex86mx/build

(5) Compiling and Installing the VT6655 driver

# unrar /usr/src/VT6655_Linux_src_v1.20.02_x86.rar

# cd VT6655_Linux_src_v1.20.02_x86/driver

# cp vntconfiguration.dat /etc

# make && make install

Reboot

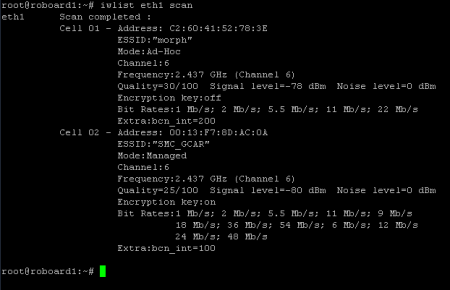

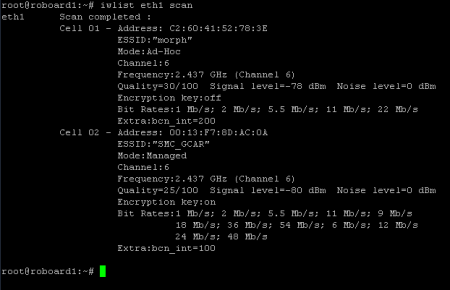

(5) Testing the card

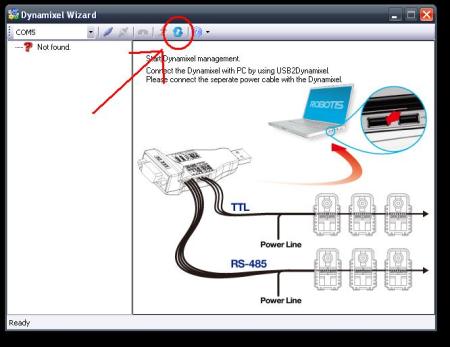

After booting, look for the card in the boot

# dmesg | grep via

[ 6.783647] eth1 (viawget): not using net_device_ops yet

To test the card, for example try just to lookup for avaliable wireless networks, put on terminal

# iwlist ethX scan

Where ethX is your ethernet wireless and the return is looked like

To configure your network we can also give some hints.

Using wpa supplicant method, edit the /etc/network/interfaces file and add another ethernet interface, your wireless interface, for example like this

# This file describes the network interfaces available on your system

# and how to activate them. For more information, see interfaces(5).

# The loopback network interface

auto lo

iface lo inet loopback

# The primary network interface

auto eth0

allow-hotplug eth0

#iface eth0 inet dhcp

iface eth0 inet static

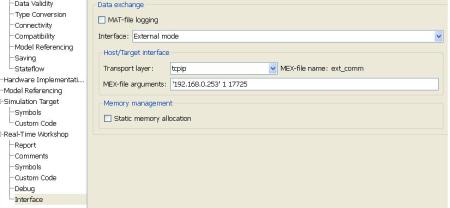

address 192.168.0.252

gateway 192.168.0.1

netmask 255.255.255.0

network 192.168.0.0

brodcast 192.168.0.255

# the wireless interface 1

auto eth1

allow-hotplug eth1

iface eth1 inet dhcp

wpa-conf /usr/src/wpa_supplicant.conf

…

Where our device is configured as dhcp and the configuration file wpa_supplicant.conf is in the folder /usr/src.

Now you can look at http://linux.die.net/man/5/wpa_supplicant.conf to see how to build your network access configuration file.

Enjoy